Unlocking Business Growth and Innovation in Electronics and 3D Printing Industries: A Deep Dive into the Role of Advanced Asphalt Plant Technologies

In today's rapidly evolving market landscape, industries such as Electronics and 3D Printing stand at the forefront of technological innovation, demanding businesses to adapt swiftly, embrace automation, and prioritize sustainability. Among the numerous technological advancements, the significance of robust infrastructure solutions such as asphalt plants cannot be overstated, especially for companies involved in manufacturing, construction, and logistics. This comprehensive guide explores how businesses are leveraging cutting-edge technologies to achieve excellence, with a special focus on asphalt plant innovations that catalyze industrial growth.

Understanding the Dynamics of the Electronics and 3D Printing Industries

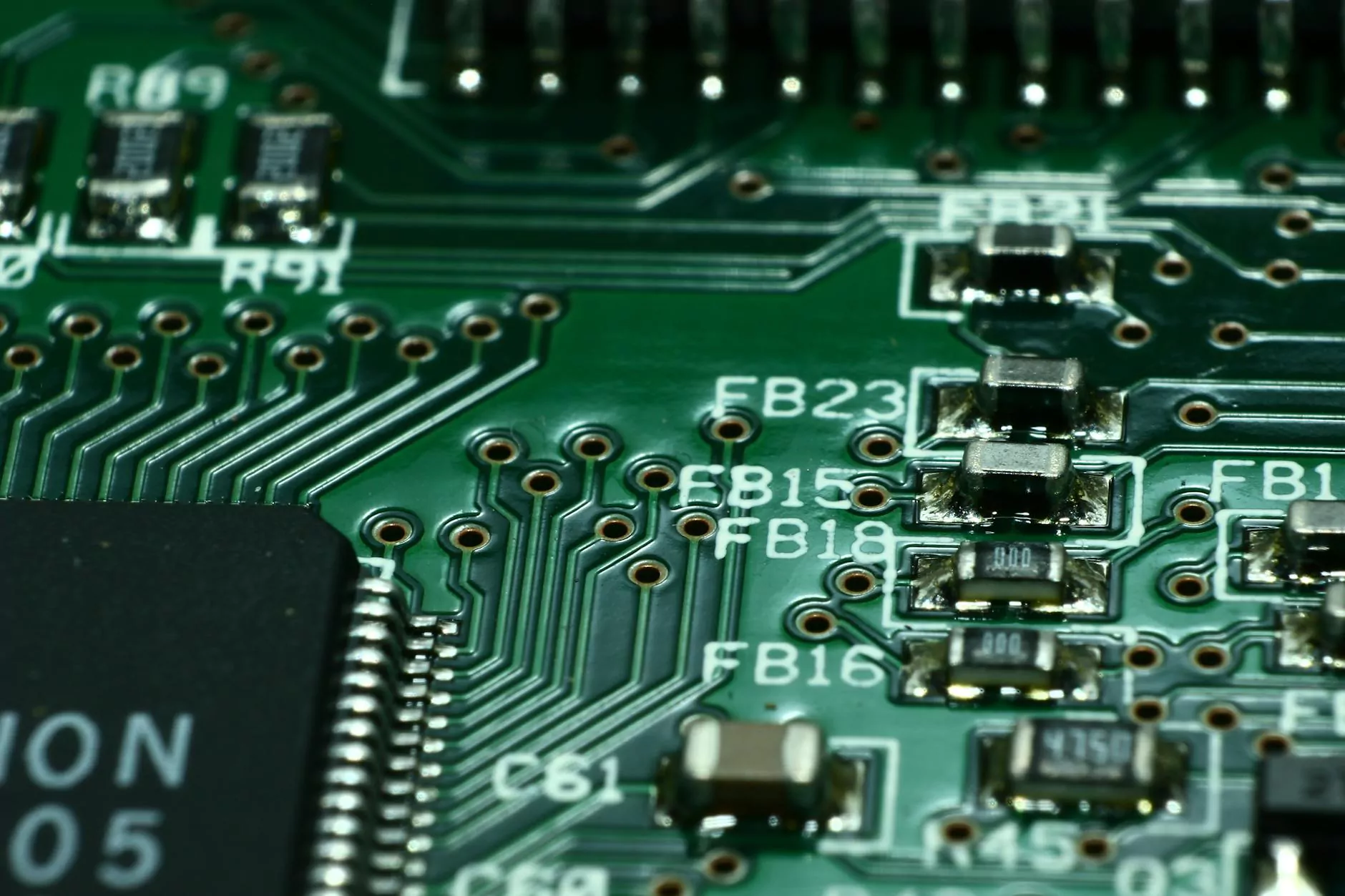

The Electronics industry is characterized by rapid product development cycles, complex supply chains, and relentless consumer demand for innovative gadgets. As technology advances, the integration of IoT, AI, and big data analytics becomes crucial for staying ahead. Meanwhile, the 3D Printing sector revolutionizes manufacturing by enabling rapid prototyping, custom production, and complex design realization with minimal waste.

Both sectors share a common need for dependable infrastructure and efficient supply chain logistics. This reliance underscores the importance of comprehensive solutions that include not just high-tech machinery but also durable, high-capacity asphalt plants for transportation and construction projects that support these industries’ growth.

The Interconnection Between Industry Innovation and Infrastructure Development

At the heart of sustainable business development lies the intricate relationship between innovation and infrastructure. For instance:

- Electronics manufacturing requires resilient supply chain infrastructure, which depends on reliable road networks established with advanced asphalt plants.

- 3D Printing facilities often expand to industrial zones where construction involves significant paving and roadwork, again demanding high-quality asphalt production.

- Global expansion and urbanization initiatives further amplify the need for dependable infrastructure, making asphalt plant technology a crucial component of the logistics backbone.

Revolutionizing Asphalt Plant Technology: Key Innovations for Modern Business Needs

Innovative asphalt plant technology has transformed traditional paving and construction processes, providing industry-specific benefits such as:

- Enhanced Efficiency: Modern asphalt plants feature sophisticated drying and mixing systems that significantly speed up production cycles, helping businesses meet tight project deadlines.

- Sustainability: Equipment now incorporates recycled materials, reduces emissions, and optimizes energy consumption, aligning with eco-conscious business strategies.

- Customization: Tailored asphalt mixes for diverse project requirements ensure durability, safety, and cost savings for infrastructure projects supporting electronics and 3D printing facilities.

- Automation and Data Integration: Smart control systems enable real-time monitoring, predictive maintenance, and precise mixture control for maximum versatility and productivity.

How Entrepreneurs and Business Leaders Can Leverage Asphalt Plant Innovation to Drive Industry Success

Strategic investment in cutting-edge asphalt plant technology offers tangible advantages:

- Cost Reduction: Efficient production methods and recycled materials lower overall project costs.

- Faster Project Turnarounds: High-capacity plants facilitate rapid deployment of infrastructure, crucial for industries like electronics manufacturing corridors and 3D printing parks.

- Sustainable Practices: Eco-friendly asphalt solutions meet regulatory standards and corporate social responsibility commitments.

- Market Differentiation: Advanced infrastructure enables faster distribution channels, better logistics, and increased competitiveness on a global scale.

Building a Resilient Business with Robust Infrastructure Solutions

To succeed amidst fierce competition, companies must adopt integrated strategies that encompass technological innovation across their core operations and infrastructure. Notably:

- Investing in High-Quality Asphalt Plants: Choosing state-of-the-art equipment from reputable providers ensures operational longevity and flexibility.

- Integrating Industry 4.0 Technologies: Embedding IoT sensors, automation, and data analytics within asphalt plant operations enhances efficiency and predictive maintenance.

- Fostering Sustainability: Incorporating recycled materials and emission controls aligns with global eco trends and future regulations.

- Strategic Location Selection: Ensuring manufacturing hubs are accessible through reliable transportation networks paved with high-quality asphalt that incorporates innovative plant solutions.

The Role of Polygonmach in Industry 4.0 and Infrastructure Innovation

Leading manufacturers like Polygonmach are at the forefront of providing asphalt plant solutions that integrate the latest in automation, environmental friendliness, and versatility. Their machinery offers:

- Modular Design: Facilitates easy transportation and assembly tailored to project needs.

- Energy Efficiency: Reduced operational costs with low fuel consumption and advanced heat recovery systems.

- Smart Control Systems: Enables remote operation, real-time data tracking, and predictive analytics for maintenance and quality control.

- Eco-Friendly Technologies: Meets stringent emission standards while utilizing recycled materials, which is vital for sustainable urban development supporting electronics and 3D printing businesses.

Emerging Trends and Future Outlook in Business Infrastructure and Industry Innovation

The future landscape of electronics and 3D printing industries will heavily depend on the continuous evolution of infrastructure materials and technologies. Key trends include:

- Green Asphalt Technologies: Increasing use of bio-based binders and recycled asphalt to reduce carbon footprint.

- Artificial Intelligence Integration: Advanced AI-driven systems for optimizing asphalt mix design and plant operations.

- Automated Construction Equipment: Robotic paving and drone-based site monitoring that require highly reliable infrastructure for seamless operation.

- Smart Cities and IoT: Infrastructure that supports connected technologies, requiring high-tech asphalt solutions compatible with future urban environments.

Conclusion: Strategic Infrastructure Investment as a Catalyst for Industry Leadership

Through embracing innovative asphalt plant technology and aligning infrastructure development with industry-specific needs, businesses in Electronics and 3D Printing sectors can achieve unparalleled growth, operational efficiency, and environmental responsibility. The synergy between high-tech manufacturing and cutting-edge infrastructure solutions paves the way for a resilient, sustainable, and competitive future.

Invest in high-quality asphalt plant machinery, prioritize digital transformation, and adopt eco-friendly practices to foster lasting success. As industry leaders like Polygonmach demonstrate, synergizing technology and infrastructure is the key to unlocking your business's full potential in today’s innovative economy.